Related websites

-

INSA Rennes

INSA Rennes is a member of the INSA Group, the leading French network of state graduate and post graduate engineering schools. INSA Rennes stands out for two poles of excellence: Information & Communication Sciences & Technologies and Materials, Structures & Mechanics.

-

University of Rennes

The University of Rennes brings together training departments, research centres and five grandes écoles who participate in the development and implementation of the strategy of the University of Rennes.

Other topics:

Flows of particles through a porous medium

Presentation

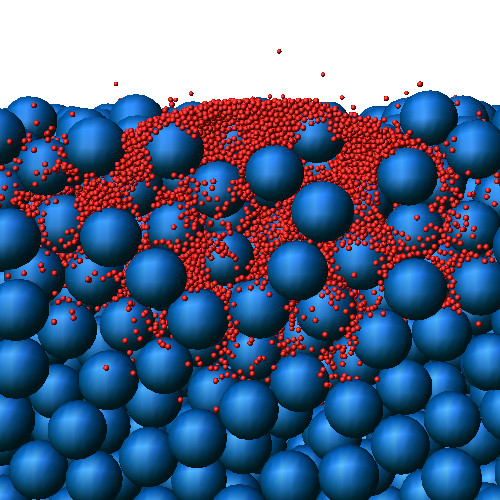

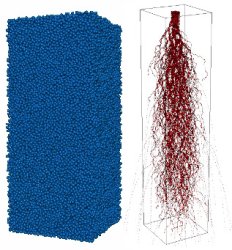

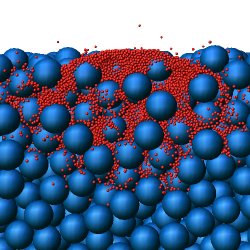

The handling of granular material is often the source of many difficulties. One of them is size segregation, which implies a non-homogeneous distribution of the different types of grains, making it very difficult to achieve homogeneous mixtures. In this work, I was interested in the phenomenon of spontaneous interparticle percolation in a granular medium.

The phenomenon of spontaneous interparticle percolation is defined as the movement of fine particles through an arrangement of larger spheres under the simple effect of gravity. The energy is then dissipated during the collisions that lead to a longitudinal and transverse dispersion of the particles. The interest in understanding the phenomena governing this type of transport is justified by the problems encountered by industries using granular materials (pharmaceutical industry, food industry, civil engineering sector, ...). To be able to mitigate the segregation phenomena which appear when we try to mix two or several types of grains is of important in the industrial sectors previously mentioned.

In addition, a dispersive process such as the one previously mentioned, proves to be a simple and effective way to obtain homogeneous mixtures. Nevertheless, to achieve this, the knowledge of the influence of the different parameters involved is necessary. This work is articulated around two complementary axes: an experimental part and a numerical part.

Experiments

Experimentally, we can study the variations of the mean transit time as a function of the height of the granular packing, the restitution coefficient, the size ratio between the particles in transit and grains constituting the porous structure, the number of particles injected into the medium, etc. We can also determine the dependency of the particle distribution at the exit of the porous medium as a function of these same parameters. This allows us to determine the measurement of the dispersion coefficients. More information on this device and the results obtained are available in the following references: Lominé and Oger, 2006; Lominé, 2007, Lominé and Oger. 2009.

Numerical simulations

The use of numerical simulation allows us to directly study particles flow inside the porous structure. It allows a total control of the physical parameters involved in the interparticle percolation process and also allows the measurement of various quantities that are usually difficult to access experimentally.

After the generation of sphere packing which constitute the granular porous structure, the dynamic part of the simulation is treated, in a first approach, by a method of molecular dynamics of hard spheres (Event-Driven). In this case, the collisions are by default processed in binary and instantaneous ways. Non-instantaneous contacts between several particles can nevertheless be modeled by an improvement of the classical Event-Driven method known as tc-model. This method does not require temporal integration.

In another approach, the dynamic part of the simulation is processed by a discrete element method (DEM) of deformable spheres. This method is very well adapted to natively manage contacts between several particles. Due to the fact that a time integration of particle positions is required in this method, it is generally more cpu time consuming than the previous one. These numerical studies were carried out using the developed codes (P3Ded and P-MLG3Dmd ).