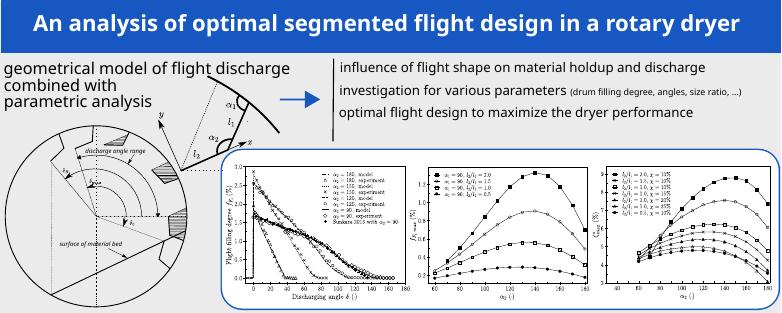

An analysis of optimal segmented flight design in a rotary dryer

In this paper, an analysis of the optimal design for two-segmented flight is performed with the aim to obtain some practical recommendations for the design of a rotary dryer. Using a geometrical model, validated with experimental results, flight loading and unloading are studied over the range of every possible angle between the flight segments. Maximum volume carried out by the flight, the maximum discharging angle and the mean falling height of material are computed for all configurations. Influence of size ratio between segments and drum radius are also investigated. By determining the curtain filling degree and the cumulative transfer area of material over one drum revolution, we estimate what the best flight design is, in order to maximise the contact surface between material and air flow necessary to increase the dryer performance.